Aluminium Transom Corrosion - Repair Advice

Hi Everyone

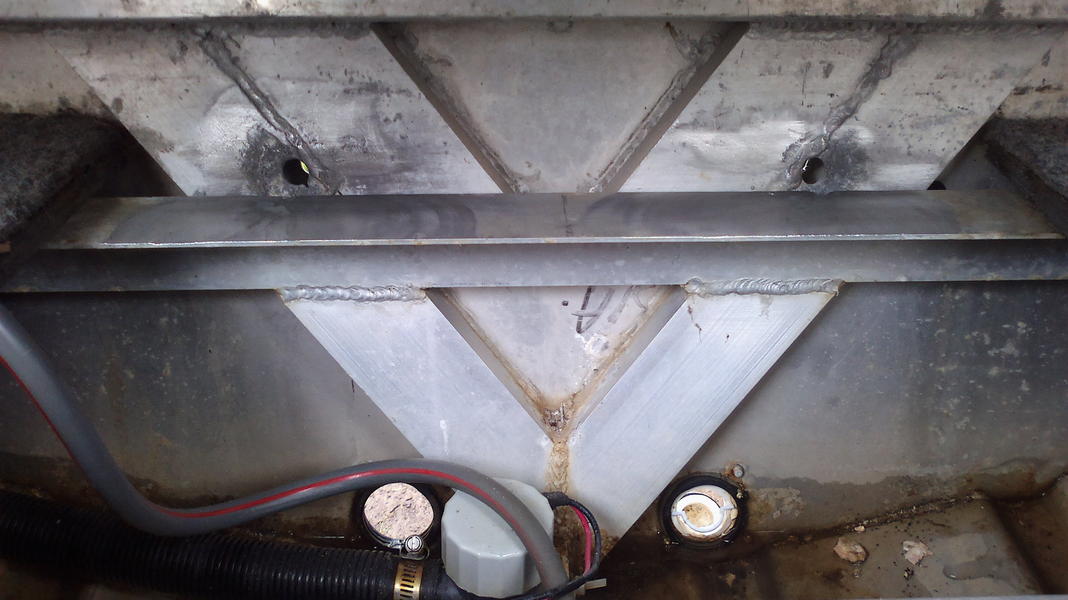

I'm hoping to get some advice on the extent of the corrosion found on my Savage Cobia's transom.

While replacing my PTT unit recently, which required removal of my outboard (to separate the bracket), I decided to replace the ply transom pad with a nylon type.

Turns out the ply pad was only riveted on without any additional sealant and has caused corrosion to the outside of the transom. After hitting it with a bristle wire brush attachment on the grinder, it turns out there is one resulting hole about the size of a pea, as well as some pitting which appears to be up to 1-1.5mm deep in places, but nothing of grave concern, I hope!.

I've recently had the anodes replaced on motor and bracket, and yesterday found a few lead sinkers under the floor but don't believe they have been there for long. I did also find a brass swivel which will have been there for longer than I have owned the boat (16 months) as I don't believe I or anyone else uses brass swivels. I don't use a battery isolator which I've found out I should so will look to get that sorted out pronto.

I've attached some pics of the transom, showing outside, upper inside, and lower inside (to show either side of the engine mounting holes). I'm hoping that cleaning it up a bit further, drilling out the rivet and corrosion holes, weld them up and weld an additional 4mm plate over the top will be all that is required, but unsure whether any of the existing ali should be cut out out first? Will the corrosion continue if I ensure that the battery is regularly isolated, and all dissimilar metals in contact are duralac'd?

I've had a fabrication place (not boat specific) carry out some re-welding on some cracked welds (and other non-boat things) at a very reasonable price and did an excellent job, so was considering going back there but happy to look at other options, companies etc.

The plan is to keep this boat for as long as I foresee as it's my baby and does everything that I want it to and takes me where I want to be.

Look forward to hearing thought/opinions. Thanks in advance!

Cheers

Craig

carnarvonite

Posts: 8701

Date Joined: 24/07/07

Plate

Looks like you could probably plate over top of it without too much trouble but if it was mine I'd be cutting the piece out and replacing the corroded bit

trymyluck

Posts: 908

Date Joined: 06/05/12

yeah I hear you Craig , it

yeah I hear you Craig , it pisses me off so much when you buy a new boat and within a short time electrolysis sets in !! Even if you take all the proper precautions.

Pity there isn't more options with Poly boats.

craig_johns469

Posts: 29

Date Joined: 06/03/12

Cheers...

Thanks Carnarvonite - I'll get pricing for both, and if it seems to be the recommended method, I can always cut out the corroded areas myself and prep the replacement material so that all I'm having to outlay is the welding cost.

Cheers Trymyluck - I've been really happy so far with the tub, and it's actually a 1996 model but is in excellent condition overall (and the Cobia has been referred to as a "battleship" as far as build quality goes). I'm glad I've caught it pretty early and I've definitely learned a valuable lesson. I'll be doing everything I can to prevent anything like this happening in future.

sea-kem

Posts: 15209

Date Joined: 30/11/09

I would just plate it. It

I would just plate it. It will strengthen the existing plate. Trying to cut that out and butt weld in new plate will be an absolute pain in the ass. Trust me I'm a fabricator.

Love the West!

craig_johns469

Posts: 29

Date Joined: 06/03/12

Thanks again...

Cheers Sea-kem

I did think that after I put up that last reply. I read on another forum, someone had had some welding done which looked perfect but still leaked so was having to take it back.

If that's the way I go (plate over it), I think it's still worth getting the rivet and corrosion holes filled first - your thoughts?

As far as strength, I'm not overly concerned as there is still a lot of meat there and I really don't think it will be too affected in the strength department, but as you said, additional plate will strengthen it back to or beyond the original. My main concern is stopping the corrosion from continuing.

On that, is there much likelihood that corrosion will continue after this was done, provided that I've removed all dissimilar metals and installed an battery isolator? I'm hoping it's not a "once it's started, it's difficult to stop" scenario.

Thanks again for all the info, everyone.

Craig

sea-kem

Posts: 15209

Date Joined: 30/11/09

Yeah you can try and weld

Yeah you can try and weld the holes up but they will be a pain in the arse to do as the ali will be impregnated with salt and other impurities. It looks like the bolt holes going through the tube are hollow? Might be worth running some pipe through there and weld up as well for strength and stop water filling up the tube.

Love the West!

grantarctic1

Posts: 2546

Date Joined: 03/03/11

It will

It will continue to corrode underneath a plate welded on top of the problem area , But i would probaly go that way my self to save time and cutting into the transom. Sometimes if you cut out an area like the transom , it will go out of shape and its hard to get the area straight again.

So i suggest if you plate over the area, add a couple anodes to the hull or transom to attract the corrosion away from the repair .

Cheers Grant .

craig_johns469

Posts: 29

Date Joined: 06/03/12

Good idea Grantarctic1....

...adding the extra anode or two, that is...

I'll look to clean up the existing plate as much as possible which will thin it out a bit, but won't be a problem with extra plating welded over the top.

Thanks for your advice, much appreciated!

Craig

petermac

Posts: 2946

Date Joined: 03/03/10

bullet boats

email some pics to willie from bullet boats in rockingham I recon he could help you out

squidder

Posts: 457

Date Joined: 03/09/10

Plating

over the area in question would {as previously stated}would be the best option, but cut out, punch or drill some holes in the replacement plate and TiG or Mig through these to get a better bond to the affected area.

We have done many like this on larger craft and it seems to have worked.

Xtra anodes would help as well.

sea-kem

Posts: 15209

Date Joined: 30/11/09

Yeah called puddle welding

Yeah called puddle welding Bruce. Done a lot in large sheet jobs where you can't get underneath to weld. Very affectice and will minimise distortion.

Love the West!

marrisy

Posts: 205

Date Joined: 08/09/11

some good advice there.

If you take it to a general welder, make sure the new plate is the correct grade of ally, (500 series) as if normal 6061 series plate is used, you will have electro chemical corrosion between the different grades. The specialist boat welders will have the right plate. Marrisy.

craig_johns469

Posts: 29

Date Joined: 06/03/12

Thanks everyone...

Petermac - Cheers for that - I'll get in touch with Willie (sending an email straight after this)

Squidder - Thanks for that - makes sense and is a technique I've used for extending steel tubing (10mm holes on 40mm diameter tubing, with smaller diameter tubing inside). Was going to say "puddle welding" but;

Sea-kem got in first! Cheers for that...

Marrisy - Good advice, thanks. I was going to ask about the different grades but thought I'd get in touch with Willie and/or other specific boat repairers first.

Thanks everyone for the advice - it's nice to get opinions/knowledge to hopefully have them confirmed by whoever does the job.

Cheers

Craig

pelagicyachts

Posts: 1332

Date Joined: 23/02/11

mate when you bolt it back

mate

when you bolt it back together use some duralac on the bolt shafts - plenty -it helps prevent disimilar metal pitting that will happen on any alum boat where you have two different metals.

Doesnt look too bad -plating will buy you plenty of time -

pelagicyachts

Posts: 1332

Date Joined: 23/02/11

mate when you bolt it back

mate

when you bolt it back together use some duralac on the bolt shafts - plenty -it helps prevent disimilar metal pitting that will happen on any alum boat where you have two different metals.

Doesnt look too bad -plating will buy you plenty of time -

craig_johns469

Posts: 29

Date Joined: 06/03/12

Duralac...

Cheers pelagicyachts.

Thanks for that - I'm going to get some Duralac and go over very single screw, nut bolt etc over the next month or so. I'll also be going mad with the Sika marine sealant too, in between bolts and washers, washers and nuts, washers and ali, bracket and ali etc...