Installed Dinghy Floor

Hey guys,

thought I'd put up a couple of pictures of how I have put in a cheap and effective flooring in my tinny.

Firstly, went to Bunnings and bought some light weight metal bars that drill into the ribs which act as support for the Marine Ply. Also got some 9mm AA Marine Grade Ply which was cut down to size through a bit of trial and error until it slotted in nicely. Couple of galvanised screws and it's done.

Off to BCF and grabbed some blue carpet. Drilled in 2 screws into the ply to hold it in place while I cut it to size. It really is as easy as that! A couple of extra bits like cleats, rod holders and cup holders and it's all good.

All up, about 3 hours work, and you have yourself a sturdy deck, which is light weight and strong without adding too much weight to the dinghy, and not costing too much either.

(Some pics from before, during and after)

till

Posts: 9358

Date Joined: 21/02/08

Nice job, but steel in an ali

Nice job, but steel in an ali dinghy isn't the best idea.

wildinp

Posts: 89

Date Joined: 30/03/09

not a bad effort

Not a bad effort and some good thinking! just thinking though, as the bars you have installed are steel, and the tinnie is aluminium, unless you want to chage to some ally bars, might be worth considering putting some rubber between the two types of material to reduce the risk of galvanic corrosion and eventually a leak - and maybe some cold gal where you did the cut as well.

Bruce

Posts: 527

Date Joined: 11/04/12

Thanks for the tip

Good point. Its not hard to take up anyway and insert some rubber.

big john

Posts: 8775

Date Joined: 20/07/06

DIY

Good fun in doing things yourself.

If your happy with the floor after a few trips Bruce, I'd suggest getting the steel cross sections replaced by some ali channel, with a vertical support welded in the middle to support it. Wouldnt cost much to do this, you could even make all the parts yourself and just pay for the welding.

WA based manufacturer and supplier of premium leadhead jigs, fligs, bucktail jigs, 'bulletproof' soft plastic jig heads and XOS bullet jig heads.

Jigs available online in my web store!

Bruce

Posts: 527

Date Joined: 11/04/12

Cheers

We were almost going to cut some wood (instead of ali) that runs up the middle of the dinghy as sort of a reinforcement for the steel, but after testing the strength, we thought it wasn't necessary.

If after the first trip I find it flimsy for some reason, I'll definetly do something along those lines.

carnarvonite

Posts: 8701

Date Joined: 24/07/07

Ali

Same as others have said, remove the steel and replace it with ali.

It doesn't have to be in water for electrolisis to start happening and then you will find the whole boat full of pin holes in no time flat.

Troy Summers

Posts: 408

Date Joined: 14/08/11

yep a misplaced lead sinker

yep a misplaced lead sinker in the bottom of the tinny can cause havoc.. the floor looks awesome otherwise!!! great job

sandbar

Posts: 704

Date Joined: 25/10/09

Very inspiring and agree with

Very inspiring and agree with the electrolisis. Also I think when you do change the floor supports you should not brace in the middle with risers as this will cause a "hard" spot and the hull is designed to have some flex.

Well done

carnarvonite

Posts: 8701

Date Joined: 24/07/07

Supports off keel

If you run them up off the keel you won't have any trouble, the keel isn't supposed to flex and if it does you are in deep shirt.

catchalittle

Posts: 1875

Date Joined: 04/09/08

good job

good job

Nathan

Willlo

Posts: 1490

Date Joined: 07/10/11

Didnt use any supports in my

Didnt use any supports in my Dinghy,just 12mm marine ply cut to fit and had it set down in the hull a bit lower. That looks great tho.

Call Sign - BZ785

Haynes Hunter Prowler CC

pale ale

Posts: 1755

Date Joined: 02/01/10

No supports in mine either,

No supports in mine either, just stuff the lifejackets under it for a bit of support

Tony

Posts: 165

Date Joined: 27/06/12

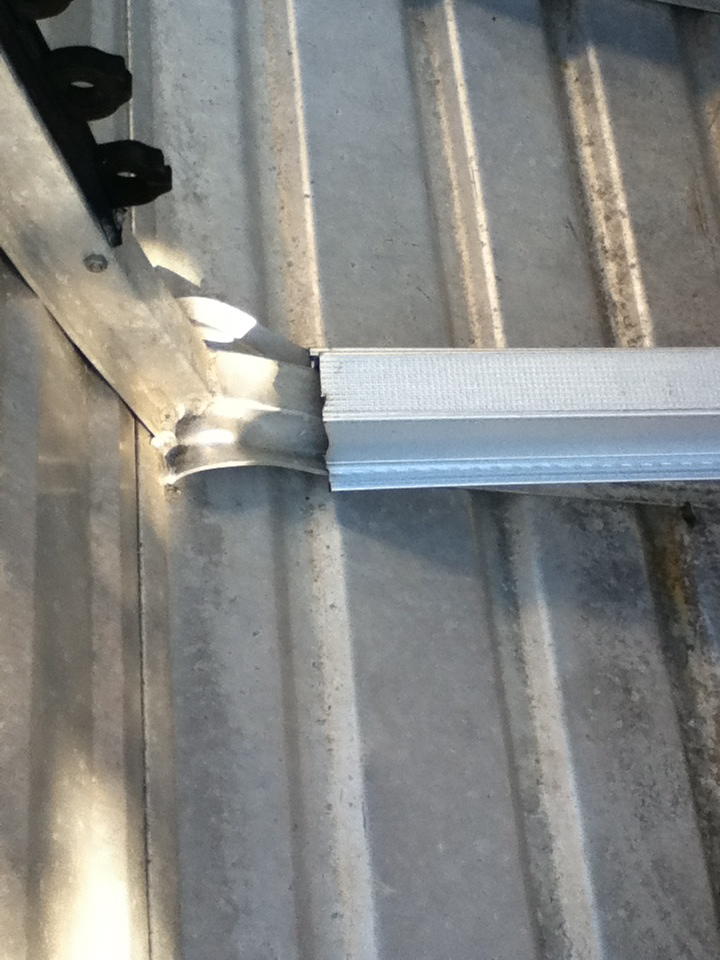

This is how I did mine, 40 x

This is how I did mine, 40 x 40 x 3mm ali angle cut to fit neatly over the ribs and existing part floor supports, short pieces for uprights from the keel, all welded solidly in position.

Tony

Posts: 165

Date Joined: 27/06/12

Marine ply cut to size and

Marine ply cut to size and three coats of marine varnish. First coat was thinned with turps at 10:1 to allow the ply to soak it up

Tony

Posts: 165

Date Joined: 27/06/12

Finnished product.

Finnished product. Marine/outdoor carpet with the rubber on the back, the carpet isn't fixed to the floor which allows removal for cleaning. The piece on the front seat is glued down so it doesn't blow out when towing.

scotto

Posts: 2474

Date Joined: 21/04/08

now that

is the ticket.

big john

Posts: 8775

Date Joined: 20/07/06

Nice

Nice job Tony.

WA based manufacturer and supplier of premium leadhead jigs, fligs, bucktail jigs, 'bulletproof' soft plastic jig heads and XOS bullet jig heads.

Jigs available online in my web store!

Tony

Posts: 165

Date Joined: 27/06/12

Thanks fellasI forgot one

Thanks fellas

I forgot one thing tho, I have pedestal and plug in base for the rear seat to install yet.

sea-kem

Posts: 15209

Date Joined: 30/11/09

Yeah bloody nice job Tony.

Yeah bloody nice job Tony. Bruce as others have said those galv top hats won't las long once they get a bit of salt water on them, same as the galv screws you mentioned. They will rust up very quick and you won't get them out. if you go to someone like Capral aluminium in Welshpool they will cut to size what you need.

Love the West!