Sand sandwich - double skin corrosion along keel line on Savage Lancer 530 - anybody come across a fix?

Hi all,

I am attempting to repair some very small corrosion holes along either side of the keel line on a pressed-aluminium Savage Lancer 530.

Unfortunately, welding spits & crackles have resulted in uncovering a very strange design (to me) aspect of this vessel.

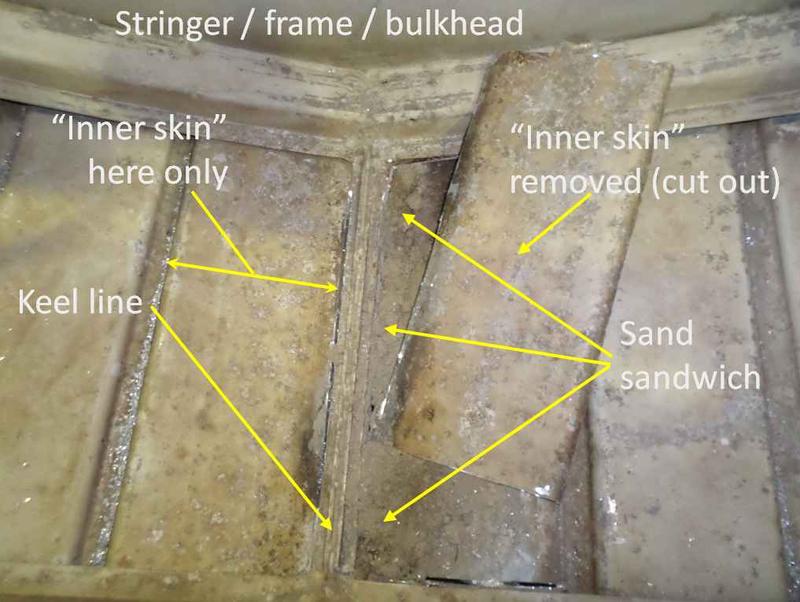

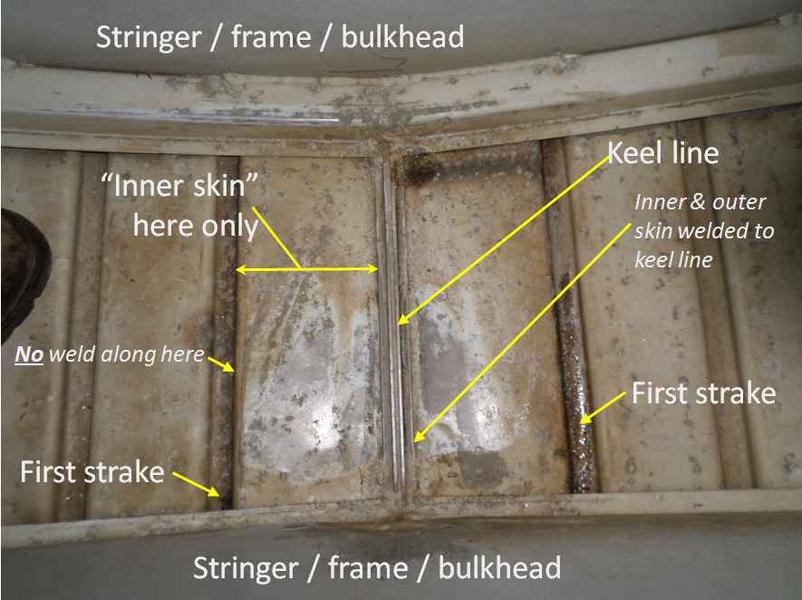

To explain… the hull is composed largely of a single-skin pressed aluminium sheeting. iIn this pressing are strakes run along either side of the keel, approximately 125mm either side of the keel line. Nothing out of the ordinary so far.

However, what’s strange to me is that on the inside of the hull is a separate sheet of aluminium which is welded to the keel line, but folded ‘down’ into the inner edge of the first strake; the first strakes being those parallel nd either side of the keel line. That is, the hull is ‘double skinned’ between the keel line and the first strake, except it’s welded along only the keel line.

The distance between the aluminium sheets is only a few millimetres, say 4mm.

The problem I have is that the design has permitted a perfect location for wet sand to accumulate between the aluminium layers making a repair almost impossible except (I suggest) by removing all the floor stringers (frames), cutting away the ‘false’ inside layer, cleaning and re-welding. Basically rebuilding the whole boat.

I would appreciate any thoughts on this, such as:

1. Has anybody come across this issue, and have they managed to solve it?

- 2. Does anybody have any idea why a narrow (125mm) sheet would be placed in such as manner? If it was intended to be structural, why weld it only to the keel line & not seal it ? My arguement is that structural integrity relies on metal not corroding, yet this design creates a terrific environment for corrosion.

- 3. Suggestions on ways to fix?

In my opinion, if I wanted the bottom of a boat to corrode away as quickly as possible and make it impossible to repair, I would have designed it in this manner!

Attached some photos to explain issue.

Many thanks in anticipation

Patch

sea-kem

Posts: 15063

Date Joined: 30/11/09

That's bizzare, never seen

That's bizzare, never seen anything like it. Are you able to contact the manufacturers to get any feed back?

Love the West!

grantarctic1

Posts: 2546

Date Joined: 03/03/11

Something wrong

Something wrong there. Is it only that section shown or the whole length of the hull ? Makes me wonder if there was a falt during manufacture and they attempted to fix or hide it .

You see this problem with some repairs, when a patch is placed over a hole or crack. Moisture and sand will get trapped and continue with the corrosion problems. However on some hulls you have no choice but to fix them with a patch. But in this case it realy seems out of place .

Sorry cant help too much, I know how hard it can be to weld old aloy, let alone with that much contamination.

ace rimmer

Posts: 187

Date Joined: 19/08/13

savage

I had a similar thing on my old Savage Osprey. Hull cracked along the keel line, welded it 2 to 3 times but still kept cracking so sold it and bought a fibreglass boat. Would never own another alloy boat and those pressed alloy boats aren't meant for open ocean like we have in Perth. cheers ACE

Patch

Posts: 2

Date Joined: 12/08/14

Thank you to all for

Thank you to all for feedback.

I attempted to contact Savage but was told they've been sold (at least) three times since this boat was built and now the name Savage is 'owned' by Telwater. I've been told all the original designers associated with this vessel have likely moved on.

It appears to me to be an original design feature, and not an afterthought, given the fact the two strips run almost the full length of the vessel and are neatly located under the stringers/frames. I don't believe it's a fault in the manufacture as it's too much extra effort. A fault in the design - now that's a different matter!

quadfisher

Posts: 1146

Date Joined: 28/09/10

Put that dirt under the carpet mate!

Yep my guess is a quick ,( not thought out ) way of making the bottom look good , as without it there maybe would be

a slight gap between the floor and the stringer,( you can see a bit near the keel line , photo 1, kinda looks like a lipstick on a pig type of thing , thats why its not structural.

good luck.

quadfisher